The Composting Process

The Composting Process

Green and Gold composting has over 12yrs experience in composting and works close with Local Authorities helping them to achieve key performance indicator targets:

Our green waste comprises of biological matter that has been cleared from local construction sites and biobased garden by-products to create compost which is a valuable resource for the agricultural and garden markets.

How we do it

Open Windrow Composting Process

Green and Gold’s compost is produced by using a technique called open windrow systems. The green waste delivered to site is firstly inspected for contamination before being shredded into a homogeneous size suitable to be stored in a windrow.

The windrow heaps are turned on a regular basis to manage optimal microbial activity, increasing oxygen uptake, disperse heat to regular temperature and to distribute moisture levels. The composting process takes an average 12 to 16 weeks depending on the maturity requirements.

Finally, the last process involves screening the compost to remove contaminants such as plastics and metals, and to also grade the compost for various end uses. Oversize organic materials are removed and recirculated back through the whole process until the material has composted down sufficiently.

Valuable end-use for organic material

Compost is used to improve the soil fertility in gardens, landscaping, horticulture, urban agriculture, home builders, sport and amenity sector and organic farming.

The benefits of compost include providing nutrients as a fertilizer to the crop, acting as a soil conditioner, increasing the humas or humic acids content of the soil and introducing beneficial colonies of microbes into the soil. The natural interaction of the soil, plant roots and nutrients of the compost improves the soil structure.

An improved soil structure will increase the soil water retention ability and control soil erosion. Green and Gold’s compost can also be used for land and stream reclamation and eco-friendly wetland construction. For landfill cover, compost provides a healthy utilisation of biobased organic materials.

Sustainability

Our Philosophy: A traditional business adapted for the Modern World.

We have embraced the modern world and its challenges, continuing to innovate and evolve with the times. We are proud to be a long-standing family-run business that is trail blazing a sustainable approach to waste and resource management in the south west of Ireland.

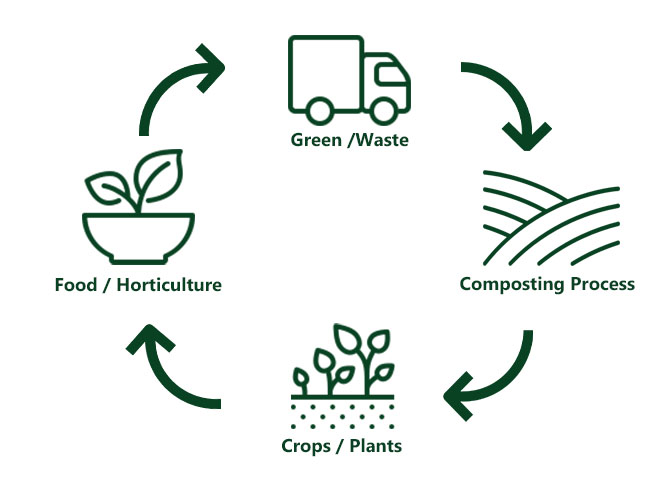

Circular Economy

- Green and Gold Composting is operated under the principles of a circular economy –This means that we aim to operate as a closed loop system – ensuring that any by-products created by our business are repurposed. We are constantly redesigning our processes and harnessing innovation to improve the efficiency of our facility.

- Our customers are at the heart of everything we do.

We believe in working together to provide quality products and services at competitive prices, whilst improving the environment and reducing carbon emissions. Our business is designed with convenience in mind. Our products and services will save your business time and money all while ensuring minimal impact to the environment. We strive to be a circular business, and this means we are continually innovating the keep up with the latest advances in sustainable technology.

Biomass – a renewable energy source

- Green and Gold Composting also supply biomass wood chip which can be reused as a renewable energy source generated from burning virgin wood chip. It is considered as a renewable form of energy production as biomass growth removes carbon dioxide from the atmosphere and stores it in the soil, plants or trees. Additionally biomass energy production process releases much less carbon dioxide (CO2) compared to fossil fuels.

Quality Assurance

All compost products manufactured by Green and Gold Composting Ltd meets with the certified requirements of the Compost Quality Protocol. For our customer this offers total quality assurance that covers every aspect of the composting process:

- Strict controls on input materials.

- Full traceability of material from waste provider to composter user.

- Hazard Analysis and Critical Control Point. (HACCP)

- The standard is externally assessed and audited annually.

- Products are manufactured to meet the requirements of the specific end markets.